1.0 General Specifications

There shall be furnished one (1) one only Grind Hog™ Model 10LSX Comminutor as manufactured by G.E.T. Industries Inc. Rotation shall be in a

▢ clockwise (standard) / ▢ counter-clockwise (optional) direction.

1.1 Design Criteria

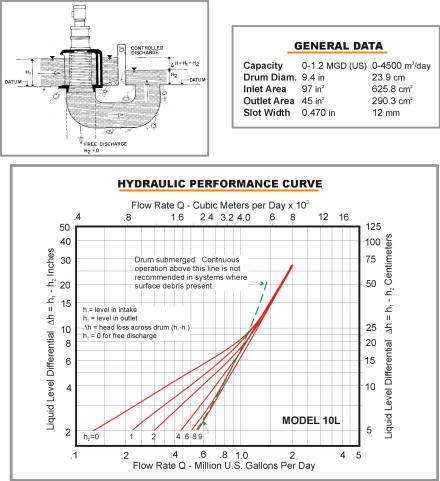

The comminutor shall be designed to handle the flows indicated below, within the head loss noted.

- a) hydraulic capacity 1.2 MGD (4500m3/day)

- b) satisfactory operation shall occur under conditions of zero flow

- c) head loss at peak flow shall not exceed 10 inches (254 mm)

- d) design shall be such that the flow enters the size reduction and screening device horizontally and exits vertically downward to facilitate the flushing of solids

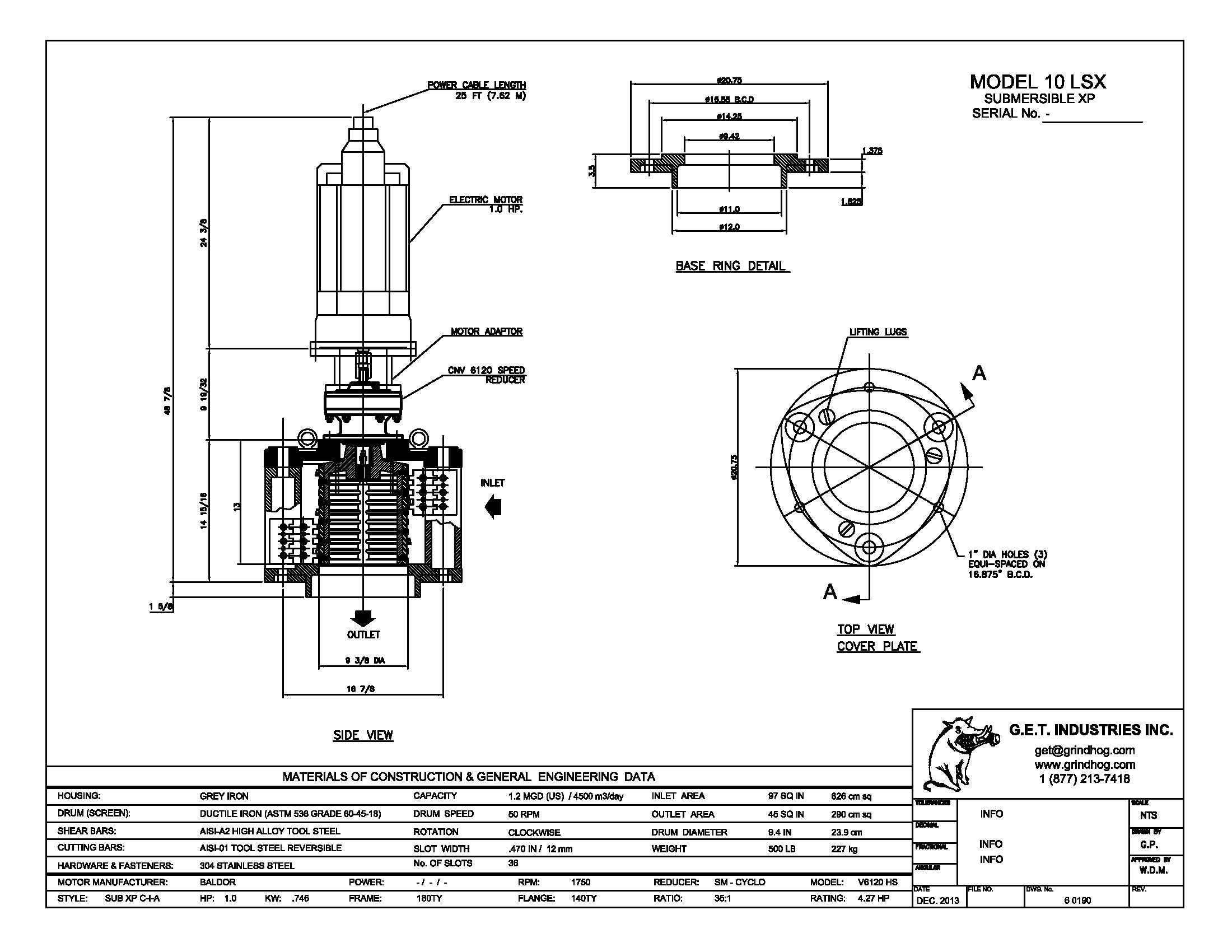

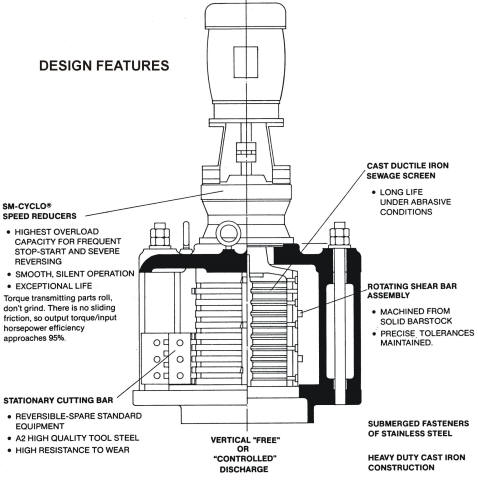

1.2 Casing and Curb Ring

Shall be:

- a) of heavy-duty construction and of high quality cast iron

- b) machined flat and complete with three (3) holes for anchor bolts

- c) of the open type allowing free access for complete cutting bar and shear bar mechanism maintenance and inspection without dismantling the unit

1.3 Rotating Drum Screen

- a) heavy-duty Cast Ductile Iron ASTM 536, grade 60-45-18

1.4 Cutting Elements

- a) replaceable shear bars constructed of high-quality A2 tool-steel shall be attached to the rotating drum. Each shear bar shall be machined from solid bar stock, surface ground to establish exact tolerances

- b) stationary cutting bars (3) shall be of high-quality 01 tool steel hardened to a minimum of 56 Rockwell C, and shall be reversible, allowing for four (4) sets of cutting edges prior to sharpening or replacement

- c) all submerged fasteners shall be of stainless steel

1.5 Motor

Submersible, Explosion-proof 1 Hp. (.746 kw), 1750 RPM ______ volt, 3 phase, 60 HZ, rated for continuous-in-air or submerged in sewage service. Power control cable of 25 ft (7.6 m) included. Class 1, Group C and D, Division 1 Hazardous locations. The motor shall feature:

- Frame - rugged cast iron ASTM type A-48, class 30

- Hardware - 316 stainless steel

- Stator Insulation - specially treated class "F" and "H" non-hydroscopic insulation with multiple dips and brakes. Phase insulation included for inverter duty

- Rotor - die cast aluminum, dynamically balanced. Exceeds NEMA limits per MGI - 12.06

- Shaft - high strength 416 stainless steel

- Bearings - specially adapted for vertical assembly. Both upper and lower bearings are pre-packed and sealed for life with special high temperature grease

- Cable Entry System - epoxy sealed butt spliced connect for non-wicking cable entry design

- Moisture System - two wire /two probe monitoring system constantly monitors oil chamber and stator housing for moisture

- Seals - tandem (dual) shaft steal system working independent of each other. Designed to withstand 100 PSI at all seal locations

1.6 Drive Arrangement

- a) the motor shall be close-coupled to a speed reducer drive, a heavy duty planetary gear of the totally enclosed non-vented type suitable for total submergence during emergencies

- b) double seals on the output shaft shall ensure flood-proof operation through a reduction ratio of 35:1

- c) the cycloidal reducer shall be capable of withstanding shock loads to 500% of its mechanical rating of 4.27 Hp. and be warranted for two (2) years

- d) the drive shall have a minimum full load efficiency of 90% and be pre-lubricated with grease, requiring routine maintenance every 500 to 1,000 hours

A) "KWIK-LIFT' WET WELL REMOVAL SYSTEM

The Comminutor shall be equipped with a slide rail system which will allow the Grind HogTM to be removed without entering the wet well. The guide rails shall be 304 schedule 40 stainless steel pipe, 1.5 inches in diameter, and shall be of adequate length as shown on the drawings. Guide rail support shall be 304 stainless steel and shall be mounted to the wet well wall. All attaching hardware shall be of stainless steel and shall be supplied by the contractor.